Learn about Mobile Shelving from an Expert!

Mobile shelving has been called by many names over the years. Names such as "compact shelving", "high density shelving", "rolling files", "space saver shelving" and "aisle saver shelving" are the ones I hear the most.

If your main goal is to maximize the storage capacity of a room, then high density mobile shelving is a product you "may" want to consider for the task.

Notice I said "may".

Mobile shelving has been touted by many people as the best solution for every filing or storage problem! But that is far from the truth in many cases!

Read my page Setting Up a Filing System to get a better idea of all the factors that need to be considered.

Get educated or if you don't have the time, work with a mobile shelving expert to determine the best solution. It is important to understand the pro's and con's of mobile shelving, before making a decision. But before we talk about the pro's and con's I want to explain the concept of mobile shelving. I have found the pictures below to be helpful.

Mobile Shelving Concept

Far Left Picture above shows fixed shelving in a traditional layout that would be found in a library, file room, or storage area. With fixed shelving an aisle is required in front of every unit for people to access the contents of the shelving.

Middle Left Picture above turns the fixed shelving into mobile shelving by mounting the fixed shelving on carriages that roll on tracks installed on the floor. Putting the shelving on carriages that roll allows us to eliminate all the aisles except for one (you can build more than one aisle into a system if you desire). Same storage capacity in half the floor space!!

Middle Right Picture shows the entire area filled with compact shelving. Under this layout we have doubled the storage capacity of the area!

Far Right Picture shows the left over space and let's the client decide what to do with the space. Maybe you need more workstations, a copy center, conference room, display area or you fill in the blank. Other client's give the space back to the landlord to reduce their rental costs!

Types of Mobile Shelving

Manual Mobile Shelving System

There are three types of mobile shelving. The types are defined by how the system moves.

The most basic of high density mobile shelving systems is the manual system. Pull/push handles are mounted at the end of each mobile carriage and the user must push or pull the carriages to create an access aisle.

Less than 5% of the systems I have sold over the years fall into this catagory. The main reason is no one wants to move all the weight without some assistance. Manual systems are limited to carriage lengths of 8' or less in most instances and mostly inactive areas.

Some of the most common applications for Manual Systems are, Medical Records Storage, Medical Supply Storage, Office Supply Storage, Legal File Storage, Retail Store Backroom Storage, Mailroom Supply Storage and Closet Storage.

Click here for help designing a Manual System.

Mechanical Assist Mobile Shelving System

Mechanical Assist systems are the most popular type of high density mobile shelving system, representing 80% of the marketplace. They move when a user turns a handle at the end of a carriage. The handle turns a chain which is attached to a drive shaft inside the carriage. The drive shaft turns the wheels which make the carriage move.

Carriages come in lengths from 3' to over 50' and can accomodate files, file cabinets, books, archive boxes, office supplies, spare parts, binders and a thousand other types of media or materials.

The first question to come up with these systems is, "Isn't it hard to move all of that weight by just turning a handle?"

The answer is, no.

High quality mechanical assist systems utilze gear reduction technology that allows the user's 1 lb. of effort to move anywhere from 3,000 lbs. to 10,000 lbs of weight.

The first comment I hear after a system is installed is, "I can't believe how easy it is to move a carriage." In fact it is not uncommon to be able to move 2,3 or even 4 carriages at one time.

Some of the most common applications for Mechanical Assist Systems are, File Storage, Book Storage, Archive Box Storage, Museum Storage, Office Supply Storage, Parts Storage and Police Evidence Storage.

Click here for help designing a Mechanical Assist System.

Electric Mobile Shelving System

Electric Mobile Shelving systems are the fastest growing part of the mobile shelving industry. They currently represent about 10-15% of all systems installed. These systems offer push button operation for the fastest access and when configured properly they offer multiple safety systems to protect the users.

The carriages of electric systems come in lengths starting at 6' and can extend well past 50'. An electric motor takes the place of the hand crank making it is possible to move all carriages in the system at the same time with the simple press of a button.

Money Saving Tip: 70% of the cost of a filing is the labor involved in doing the physical filing, being able to move all the carriages at once with an electric system greatly reduces access time and improves worker productivity which equates to a lower cost of labor!

Safety is an important item to consider when purchasing an electric mobile system. If you cannot afford to put the best safety systems into use with your system, it is better to purchase a mechanical assist system. In the effort to offer equipment at the lowest price point most manufacturers will only offer their minimum safety system ( as little as a safety sweep on the face of the carriage). I personally think putting your own self interests of making the sale in front of the end users safety is a terrible idea! So lets talk about what safety systems you should be asking for.

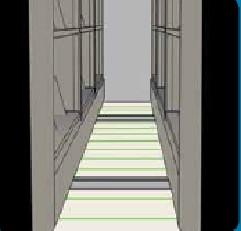

Light Carpet is the safety system with the best overall aisle coverage. Invented by White and currently owned by Borroughs, the Infrared sensors scan the entire floor of the system, they are spaced on 3" centers the green lines represent the coverage. Light carpet tracks up to four separate users as they enter and leave an aisle, it even knows if a person were to climb up the shelving. With the sensor positioned at floor level it will also detect a book or thick file left on the floor of the system. Spacesaver developed a product called Zero Force in an attempt to compete with Borroughs. Zero Force has sensors every 12" along the face of each carriage and about 4" above the floor. If you are to purchase and electric mobile shelving system, make sure it has one of these two systems. The infrared sensors are similar to what you see on garage door openers and have proven long term reliability, if a sensor is blocked the system will not move.

Motion or heat sensors have also been employed with limited success because they can be affected by HVAC systems making them troublesome if placed near ducts. What many manufactures try to pass off as safe consist of an aisle safety sweep on each side of an open aisle. Problem with this set up by itself is the equipment can move with a person inside of it, the user when the system moves will instinctively step back from the moving carriage and as a result not trip the safety until the carriages are very close to each other. The chance for some type of injury is possible.

Security is another reason to consider an electric system as it is possible to limit access to specific aisles to only those employees who have the correct 4 digit code or key fob. This is particularly helpful for systems that are shared by multiple departments or outside of locked file rooms.

Click here for help designing an Electric System.